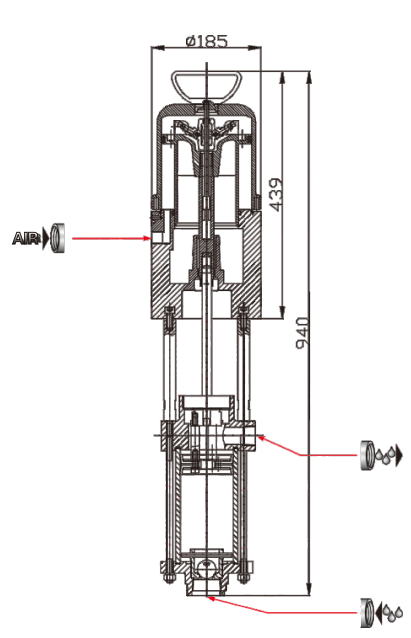

| Model | GK3:1 Pneumatic Piston Pump |

|---|---|

| Max.Working Pressure | 435psi (3.0Mpa, 30bar) |

| Max.Flow Rate | 14 gpm (53 Ipm) |

| Max.Suction Lift | 6m |

| Max.Particle Allowed | 3.0mm |

| Fluid Outlet Size | 1 in. |

| Fluid Inlet Size | 1-1/2 in. |

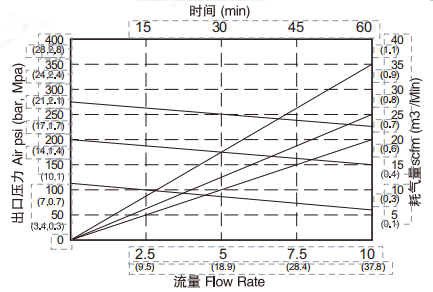

| Max. Air Consumption | 34scfm (17L/s) |

| Air Inlet Size | 1/2 in. |

| Connection Type | Female Thread |

| Body Material | 304/316(SS304/SS316) |

| Ratio | 3:1 |

Product Description

Are you searching for a reliable and high-performance piston pump supplier for your industrial needs? Look no further than GIN KAI TECHNOLOGY (SHANGHAI) CO., LTD (GK). We specialize in manufacturing top-of-the-line air operated diaphragm pumps, electric diaphragm pumps, and now, our flagship product, the GK3:1 Pneumatic Piston Pump.

Our GK3:1 Pneumatic Piston Pump is designed to deliver exceptional performance and reliability, making it the ideal choice for a wide range of fluid transfer applications. With a maximum working pressure of 435psi (3.0Mpa, 30bar), this pump ensures efficient and consistent operation, even in demanding industrial environments.

Impressive Flow Rate: Experience unmatched efficiency with a maximum flow rate of 24gpm (53 Ipm). Our pump ensures swift transfer of fluids, reducing downtime and maximizing productivity.

Versatile Suction Lift: With a maximum suction lift of 6m, the GK3:1 Pneumatic Piston Pump excels in both high and low suction applications. It reliably handles various fluids, including viscous and abrasive substances.

Particle Handling Capability: Trust the GK3:1 Pump to handle fluids containing particles up to 3.0mm in size. Its robust construction and advanced design prevent clogging, ensuring uninterrupted performance.

Durable Construction: The pump body is crafted from high-quality 304/316 stainless steel (SS304/SS316), offering excellent corrosion resistance and longevity. This ensures reliable operation even in harsh operating conditions.

Easy Installation and Maintenance: The GK3:1 Pneumatic Piston Pump features a female thread connection type, allowing for quick and hassle-free installation. Its user-friendly design facilitates easy maintenance, minimizing downtime and reducing operational costs.

Efficient Air Consumption: With a maximum air consumption of 34scfm (17L/s), our piston pump optimizes energy usage, resulting in cost savings and environmental benefits.

Our plunger pumps are widely used, examples are as follows:

Industries Involved | Applications |

Petrochemical Industry | Crude oil, heavy oil, grease, mud, sludge, etc. |

Chemical Insdutry | Acids, alkali, solvents, suspended solids, decentralized system |

Wastewater Treatment | Lime milk, Soft Sediments, Sewage, Chemicals, Wastewater |

Electronic Industry | Solvents, electroplating fluid, cleaning fluid, sulfuric acid, nitric acid, waste acids, corrosive acids, polishing solutions / liquid |

At GK, we pride ourselves on delivering exceptional products that outperform the competition. Our GK3:1 Pneumatic Piston Pump sets the industry standard for performance, durability, and versatility. Trust our expertise and experience to meet your fluid transfer needs efficiently.

Contact us today to learn more about the GK3:1 Pneumatic Piston Pump and how it can revolutionize your industrial operations. Gain a competitive edge with GK's cutting-edge solutions and experience a new level of reliability and efficiency in fluid transfer.